Why Canvas and Tent Repairs Are a Strategic Investment

Canvas and tent repairs extend the operational lifespan of your glamping infrastructure and protect your Total Cost of Ownership (TCO). For commercial operators, hunting outfitters, and high-utilization businesses, repair strategy is a core part of asset management, not an afterthought.

Quick Repair Guide:

- Minor damage (small tears, holes under 0.05 m) → DIY patch and adhesive repair

- Seam stress → Re-stitch with heavy-duty waxed thread and seal

- Zipper issues → Lubricate slider or replace track professionally

- Ember holes → Canvas patch with professional-grade adhesive

- Major tears (over 0.15 m) → Professional panel reconstruction

- Mold/mildew → Clean, treat, and reassess structural integrity

Canvas tents represent a significant capital investment for commercial operations. Unlike disposable alternatives that quickly degrade and demand full replacement, professional-grade canvas materials can be repaired and restored multiple times. This repairability fundamentally changes the economics of your tent fleet.

A well-maintained canvas tent can serve guests or clients for years under demanding conditions, while targeted repairs typically cost a fraction of replacement. This reduces lifecycle expenditure, stabilizes TCO, and limits operational downtime.

The distinction between short-lived gear and repairable assets is critical for operators managing multiple sites or seasons. Commercial-grade canvas tents are built with heavier-gauge cotton duck, reinforced stitching, and robust hardware designed for restoration. When damage occurs—and it will under intensive use—the question is not whether to replace, but how to repair in a way that supports uptime, safety, and long-term value.

Stout Tent supports canvas and tent repairs for high-use fleets around the world, from emergency field patches to full panel reconstructions. Expert-tested methods, professional-grade materials, and an understanding of tent construction allow commercial clients to maximize fleet longevity and protect return on investment across multiple seasons.

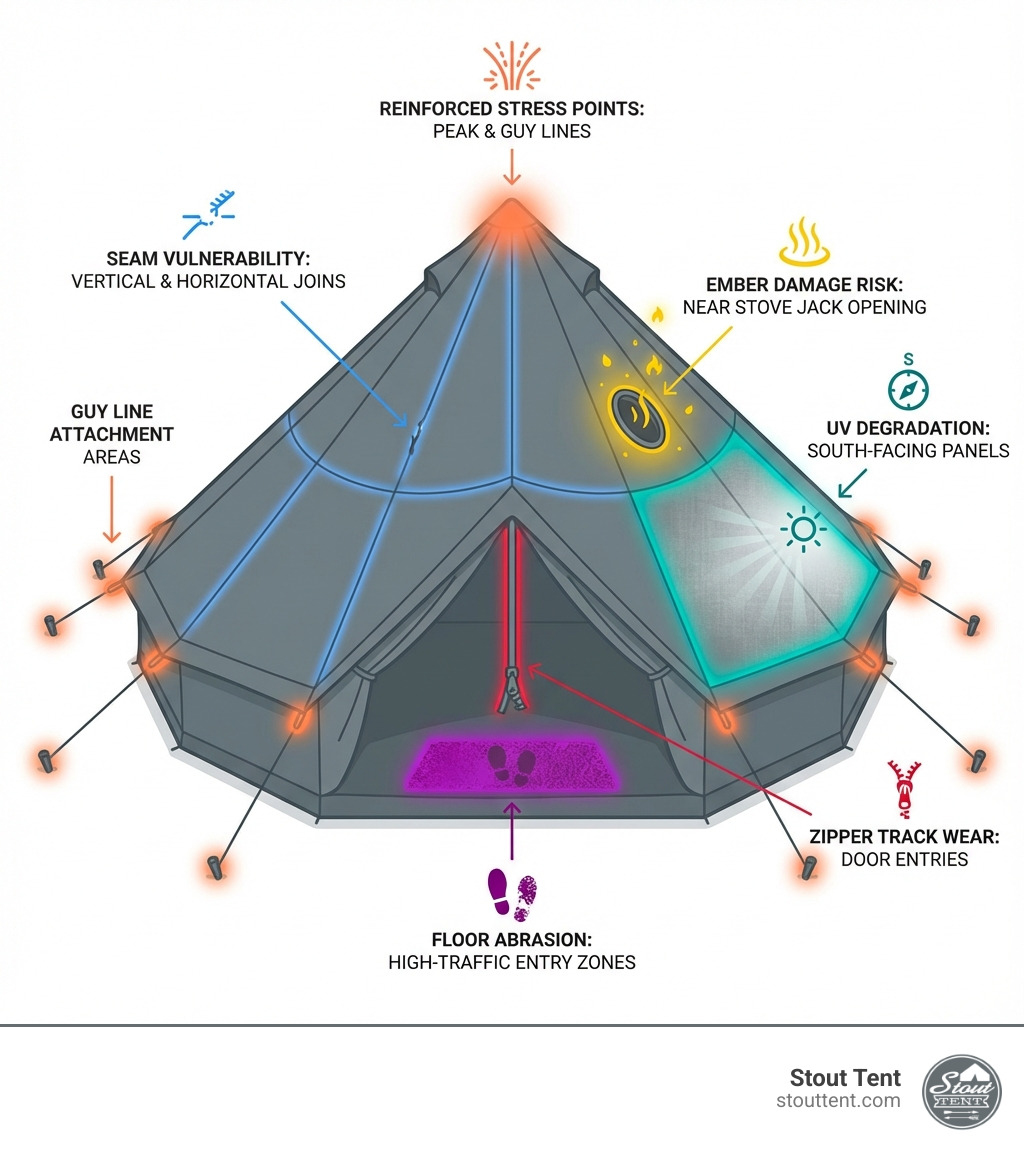

Initial Damage Assessment: Identifying Common Canvas Tent Issues

Before starting any canvas and tent repairs, a thorough and systematic assessment of the damage is paramount. This initial inspection determines the scope of repair, materials and methods required, and whether DIY intervention is feasible or if professional services are necessary. Common damage types encountered on canvas tents include:

- Tears and Punctures: These range from small snags caused by gear or branches to larger rips from sharp objects or excessive force.

- Ember and Spark Holes: A common issue, especially for tents utilizing internal heating sources like wood stoves. Hot embers can quickly burn small, circular holes in the canvas.

- Seam Stress and Failure: Over time, continuous tension, UV exposure, and moisture can weaken stitching or fabric along seams, leading to separation or leaks.

- Zipper Malfunctions: Zippers are high-wear components. They can jam, teeth can break, or the slider can become misaligned, compromising the tent’s integrity and weather resistance.

- Mold and Mildew Growth: Caused by damp conditions and improper storage, mold and mildew not only stain the canvas but can also degrade the fabric, leading to musty odor and structural weakening.

- Hardware Damage: Broken snaps, torn grommets, or damaged guy line tensioners can impair the tent’s ability to be properly pitched and secured.

Differentiating Minor from Major Damage

Understanding the difference between minor and major damage is crucial for effective canvas and tent repairs.

Minor Damage: These are typically small, localized issues that do not compromise the structural integrity of the tent. Examples include:

- Small tears or punctures (under 0.05 m) from pets, gear, or environmental factors.

- Small ember holes.

- Localized fraying of seams.

- Zipper sliders that are merely stiff or require lubrication.

These minor repairs can often be addressed with needle and thread or patch as a DIY project, saving significant time and resources.

Major Damage: These issues affect the tent’s structural integrity, weather resistance, or are beyond the scope of typical DIY repair. Examples include:

- Large rips (over 0.15 m) or extensive tears.

- Multiple, widespread holes.

- Significant seam separations affecting large sections of the tent.

- Broken zipper teeth, torn zipper tracks, or complete zipper failure.

- Extensive mold or mildew growth that has deeply penetrated and weakened canvas fibers.

- Damage to critical load-bearing points, such as where guy lines attach or main support pole rests.

For complicated repairs, professional repair shops familiar with canvas are recommended, as specialized equipment and expertise are usually required.

The Impact of Environmental Factors

Professional-grade canvas tents are engineered for resilience, but environmental factors are constant adversaries. Understanding their impact is key to minimizing damage and extending investment life.

- UV Degradation: Prolonged exposure to ultraviolet (UV) radiation from the sun can weaken canvas fibers, leading to fading, brittleness, and eventual fabric breakdown. This is particularly prevalent in sunny regions like Phoenix, Arizona, or the US Southwest.

- Moisture Damage: Beyond causing mold and mildew, persistent dampness can also lead to fabric rot and accelerate breakdown of waterproofing treatments and seam sealants.

- Pest Damage: Mice, mites, and other critters are significant threats to tents, especially during storage. They can chew through canvas, create nests, and leave behind waste that can lead to further degradation. This often occurs when tents are stored improperly or in accessible areas.

- Abrasion from Setup and Takedown: Repeated friction against rough surfaces, improper folding, or dragging the tent can cause wear and tear, particularly on high-contact areas like the floor and reinforced stress points.

Proactive maintenance and thoughtful handling significantly mitigate these risks, ensuring your tent remains a durable asset for years to come. Learn more about our durable bell tents.

Professional-Grade Canvas and Tent Repairs: Methods & Materials

Effective canvas and tent repairs demand the right methods and professional-grade materials. Our expert repair resources detail the tools and techniques critical to restoring your tent’s functionality and extending its operational life. Whether you’re performing emergency field repairs or more permanent workshop-level fixes, our expert-tested approach emphasizes durability and structural integrity, ensuring repairs hold up to demanding conditions.

Assembling Your Essential Field Repair Kit

A well-equipped field repair kit is an indispensable asset for any glamping operator or serious outdoor enthusiast. It allows for immediate action, preventing minor damage from escalating into major problems. For emergency field repairs, we recommend the following professional-grade materials:

- Heavy-Duty Canvas Patches: Pre-cut or cut-to-size pieces of durable canvas, ideally matching the weight and color of your tent.

- Professional-Grade Canvas Adhesive: A strong, flexible, and waterproof adhesive designed for canvas. Products like Bish’s tear mender glue are recommended for uncomplicated repairs where the canvas is structurally sound enough for adhesion. For quick, temporary fixes, a high-quality repair tape is an excellent emergency solution.

- Industrial Sewing Awl: A specialized tool that allows you to hand-stitch through thick canvas with a strong, locked stitch.

- Heavy-Duty Waxed Polyester Thread: Polyester resists UV degradation and rot better than cotton, and the wax coating helps it glide through fabric and adds water resistance.

- Seam Sealer: A liquid sealant to re-waterproof stitched seams after repair.

- Scissors or Utility Knife: For precise cutting of patches and trimming frayed edges.

- Marking Pencil: For tracing patch outlines.

- Rubbing Alcohol Wipes: To clean and prepare surfaces for adhesive.

- Spare Guy Lines and Tensioners: For quick replacement of damaged components.

For emergency repairs, remember the goal is to stabilize the damage and maintain functionality until a more permanent repair can be performed.

Step-by-Step Guide to Permanent Canvas and Tent Repairs

When a tent sustains damage, a permanent repair is often possible, restoring its integrity and extending its lifespan significantly. Here’s our expert-tested approach to undertaking robust canvas and tent repairs:

- Preparing the Damaged Area:

- Lay the tent flat and clean the area around the damage thoroughly. Remove any dirt, debris, or loose threads. For adhesive repairs, clean the area with rubbing alcohol and allow it to dry completely to ensure optimal bonding.

- Trim any excessively frayed edges around the tear, but try to keep the original fabric as intact as possible.

- Cutting a Canvas Patch:

- Measure the tear or hole. Cut a patch from a matching heavy-duty canvas fabric that is at least 0.025 m (1 inch) larger on all sides than the damaged area. This overlap provides ample surface area for strong adhesion and stitching.

- Round the corners of the patch to prevent snagging and peeling.

- Applying Adhesive (for tears and holes):

- Place the patch over the damaged area and lightly trace its outline with a pencil.

- Apply a professional-grade canvas adhesive (e.g., Bish’s tear mender glue) to both the patch and the tent fabric within the traced area. Ensure the glue is applied evenly and within the lines of the patch’s diameter to prevent darkening or discoloration on the edges.

- Allow the glue to become tacky (usually about 1 minute, check product instructions).

- Carefully position the patch over the damage and press down firmly. Use a heavy, flat object to apply consistent pressure for several hours or overnight to ensure a strong bond.

- Sewing for Structural Integrity (for tears, seams, and larger patches):

- For anything beyond a very small hole, stitching provides crucial structural reinforcement. Using an industrial sewing awl and heavy-duty waxed polyester thread, stitch around the perimeter of the patch, approximately 0.005 m (1/4 inch) from the edge.

- Employ a strong, interlocking stitch (like a lock stitch or saddle stitch) to create a durable, professional finish. For seams, carefully realign the original seam edges and stitch them together, reinforcing with a double stitch if necessary.

- Seam Sealing Post-Repair:

- Once any adhesive has cured and stitching is complete, apply a quality seam sealer along all new and repaired seams and around the edges of patches. This step is critical for re-establishing the tent’s waterproofing in the repaired areas. Allow it to dry fully according to product instructions.

- Zipper Lubrication and Maintenance:

- For stiff or sticky zippers, clean the teeth with a brush and apply a silicone-based zipper lubricant. Avoid oil-based lubricants as they can attract dirt.

- For broken sliders or teeth, a professional may be needed to replace the entire zipper or slider assembly, especially on main entry points.

By following these expert-tested steps and utilizing professional-grade materials, you can ensure your canvas and tent repairs are durable, reliable, and extend the functional life of your valuable assets.

Preventative Maintenance: Maximizing Your Tent’s Lifespan and ROI

Proactive care is the cornerstone of maximizing your canvas tent’s lifespan and, consequently, your return on investment. Just as rigorous maintenance extends the life of any valuable asset, meticulous attention to your canvas tent prevents damage, preserves its structural integrity, and ensures it remains a premium offering for your glamping guests. Regular inspection schedules, coupled with proper handling and storage, are essential for long-term value. View our premium glamping tents.

The Critical First Step: Pre-Shrinking Your New Canvas Tent

One of the most beneficial,, initial steps for a new canvas tent is “pre-shrinking,” also known as seasoning the canvas. This process is simple but critical for long-term water resistance and durability.

Why Pre-Shrink?

Canvas tents are made from cotton fibers. When these fibers get wet, they naturally swell and then shrink as they dry, tightening the weave of the fabric. This tightening significantly improves the canvas’s natural water resistance, making it more difficult for water to penetrate. A new canvas tent that hasn’t been pre-shrunk may “mist” or feel damp in heavy rain during its first few uses—this is normal and indicates the fibers are still settling. Pre-shrinking minimizes this initial “misting” and prepares the tent for its first true test against the elements.

Step-by-Step Pre-Shrinking Process:

- Set Up Your New Tent: Pitch your tent fully, ensuring all guy lines are taut and the tent is properly erected. This allows the canvas to stretch and settle in its intended shape during the shrinking process.

- Hose It Down Thoroughly: Using a garden hose, thoroughly douse the entire exterior of the tent. Ensure every part of the canvas is completely saturated. Pay particular attention to seams, as these are often the first areas to “mist.”

- Allow to Dry Completely: Let the tent dry fully in the sun and wind. This drying phase is when the cotton fibers contract and the weave tightens.

- Repeat (Optional but Recommended): For optimal seasoning, especially in areas with frequent heavy rainfall like the US Pacific Northwest, you may repeat the wetting and drying process once or twice. Alternatively, simply leave the tent pitched until it experiences its first significant rainfall.

This critical first step ensures your tent is prepared for adverse weather conditions from day one, contributing significantly to its long-term performance and minimizing the need for early canvas and tent repairs.

Proper Cleaning, Waterproofing, and Storage Protocols

The longevity of your canvas tent hinges on consistent and correct cleaning, waterproofing, and storage practices. Ignoring these protocols can lead to premature degradation, costly repairs, and a diminished asset value.

Cleaning Procedures:

- Regular Cleaning: After 6-10 weeks of use, or more frequently in harsher, damper environments, we recommend cleaning your tent. Begin by brushing off any dry mud, dirt, or debris with a soft brush.

- Hose Down: Hose down the tent thoroughly to remove loose particles.

- Gentle Cleaning: Prepare a solution of 4 parts water to 1 part white vinegar, or use a specialized canvas-specific cleaner. Gently clean the canvas fabric with a soft brush or sponge, working in small sections and rinsing as you go.

- Avoid Harsh Chemicals: Crucially, avoid household detergents, bleaches, or any harsh chemicals. These can strip the canvas of its natural oils, damage the waterproofing treatment, and weaken the cotton fibers. Never use high-pressure washers or washing machines, as they can damage the fabric and seams.

- Thorough Rinsing and Drying: Rinse the tent thoroughly to remove all cleaning solution residue. Allow the tent to air dry completely before proceeding to waterproofing or storage. Mold stains, once set, are almost impossible to remove.

Waterproofing and UV Protection Application:

- Re-treatment is Key: After cleaning, or if you notice water absorption, re-treating your canvas is essential to maintain its water, mold, and UV resistance.

- Application: Ensure the canvas is bone-dry. Apply a professional-grade retreatment product liberally and evenly. This can be done using a spray bottle, a plant sprayer, or even a paint roller for large surfaces. Follow the manufacturer’s instructions for application and drying times.

- Fire Retardant: If your tent was originally treated with fire retardant, consider reapplying it after cleaning, particularly if the tent is used in high-risk areas or for commercial events.

Bone-Dry Storage Protocol & Pest-Proof Storage:

- Never Pack Wet: This is the golden rule. Packing a damp tent is the fastest way to invite mold, mildew, and fabric rot. If you must pack a damp tent for transport (e.g., after an unexpected rain in California), loosely fold it and lay it out to dry completely within 24 hours.

- Clean Before Storage: Ensure the tent is thoroughly cleaned, rinsed, and completely dry before folding for storage. Dirt and vegetation can retain moisture and encourage mold growth.

- Cool, Dry, Lifted Storage: Store the tent in a cool, dry place, lifted off the floor. Garages or storage units in areas like the US Northeast can be prone to dampness, so keeping the tent off the concrete floor prevents moisture wicking.

- Pest Protection: Mold, mice, and mites are the biggest threats to tents in storage. For long-term storage, especially in pest-prone locations, consider storing the neatly folded tent inside a large, clean, plastic garbage can with a tight-fitting lid. This creates an effective barrier against pests and helps regulate humidity.

By implementing these professional-grade maintenance practices, you will significantly extend the life of your canvas tents, protect your investment, and minimize the need for unexpected canvas and tent repairs.

DIY vs. Professional Repair: A Strategic Decision

Deciding whether to tackle canvas and tent repairs internally or engage professional services is a strategic decision for any operator managing TCO. It involves evaluating the complexity of the damage, the operational risk of failure in the field, and the opportunity cost of staff time. The objective is always the same: keep assets in rotation, maintain safety and weatherproofing, and preserve capital.

When to Attempt DIY Canvas and Tent Repairs

Many minor damages can be effectively addressed through DIY canvas and tent repairs, allowing you to quickly restore functionality and minimize downtime between guest stays, hunts, or events. DIY is typically appropriate when:

- Small Punctures or Tears: Small holes (typically under 0.05 m) or clean tears in a non-structural area. These can often be patched using professional-grade canvas adhesive and a matching canvas patch, as detailed in our expert-tested repair guidance.

- Minor Seam Sealing: If a seam is weeping but not fully separated, a fresh application of seam sealer can often resolve the issue.

- Simple Patch Jobs: For ember holes or small rips, a well-applied patch with strong adhesive and optional hand-stitching (using an industrial sewing awl) can provide a durable fix.

- Zipper Lubrication: Sticky or stiff zippers often just need a thorough cleaning and application of a silicone-based lubricant to glide smoothly again.

- Guy Line or Tensioner Replacement: Replacing a frayed guy line or a broken tensioner is a straightforward task that requires basic knot-tying skills and spare parts.

For these uncomplicated repairs, using expert-tested methods and professional-grade materials can reduce service costs and keep tents operational without removing them from circulation for extended periods.

Identifying When to Engage Professional Services

While DIY repairs are effective for minor issues, there is a clear threshold where the scale or location of the damage requires professional intervention. At that point, prioritizing structural integrity and long-term reliability protects both guests and assets.

Professional repair is recommended for:

- Large or Complex Tears: Rips exceeding 0.15 m, L-shaped tears, or those in high-stress areas (like corners or near pole entry points) often require industrial sewing machines and specialized techniques to ensure a strong, weather-tight repair.

- Full Panel Replacement: If a large section of canvas is severely damaged by UV degradation, extensive mold, or a major incident, replacing an entire panel ensures the tent’s structural and aesthetic integrity and preserves long-term value.

- Structural Seam Failure: When a main structural seam has completely separated, or the fabric around the seam is severely weakened, it requires expert assessment and often a complete re-stitching with reinforced techniques to bear load safely.

- Complete Zipper Replacement: If zipper teeth are broken, the track is torn, or the slider is permanently jammed, replacing the entire zipper assembly is usually the only effective solution. This requires careful removal of the old zipper and precise installation of a new, heavy-duty industrial-grade zipper.

- Significant Mold Remediation: While minor mold can be cleaned, extensive mold growth that has penetrated deep into the canvas fibers may require professional cleaning and treatment to prevent recurrence and restore fabric performance without damaging the canvas.

- Damage to Critical Hardware: Issues with main pole sleeves, reinforced attachment points for guy lines, or other structural hardware that cannot be simply replaced.

For these types of extensive canvas and tent repairs, engaging a reputable canvas repair specialist or the original manufacturer helps ensure that every intervention extends, rather than shortens, the useful life of the tent. This approach aligns repair decisions with TCO objectives and supports consistent performance across demanding seasons.

Conclusion

The longevity of a canvas tent fleet is the result of deliberate maintenance planning and timely, professional-grade canvas and tent repairs. By understanding common damage types, implementing preventative protocols, and making informed choices between DIY and professional repair, operators protect TCO and keep high-value assets working season after season.

For high-utilization operations—whether hosting premium glamping guests, remote crews, or hunters—repairability is not just a convenience; it is a strategic advantage that stabilizes costs, reduces downtime, and safeguards the guest or client experience.

Ready to protect and extend the life of your canvas infrastructure?

Shop Our Canvas Bell Tents | Contact Us