Why Canvas Tent Stoves Are Essential for Year-Round Operations

Canvas tent stoves transform seasonal shelters into four-season operational assets. Here’s what you need to know:

Key Considerations for Canvas Tent Stoves:

- Material Construction: 10-gauge to 18-gauge steel determines durability and heat retention

- Heating Capacity: Firebox size directly impacts burn time and heat output for your space

- Portability: Fixed-body stoves offer maximum durability; collapsible models enable easier transport

- Safety Requirements: Proper stove jack installation and carbon monoxide monitoring are non-negotiable

- Multi-Purpose Value: Quality units provide heating, cooking surfaces, and gear-drying capabilities

A wood-burning tent stove extends your operational calendar from three months to twelve, enabling revenue generation during shoulder seasons when most canvas shelters sit empty. For glamping operators and commercial outfitters, this equipment bridges the gap between rustic authenticity and guest comfort expectations—guests experience the ambiance of a crackling fire while enjoying reliable warmth in sub-freezing conditions.

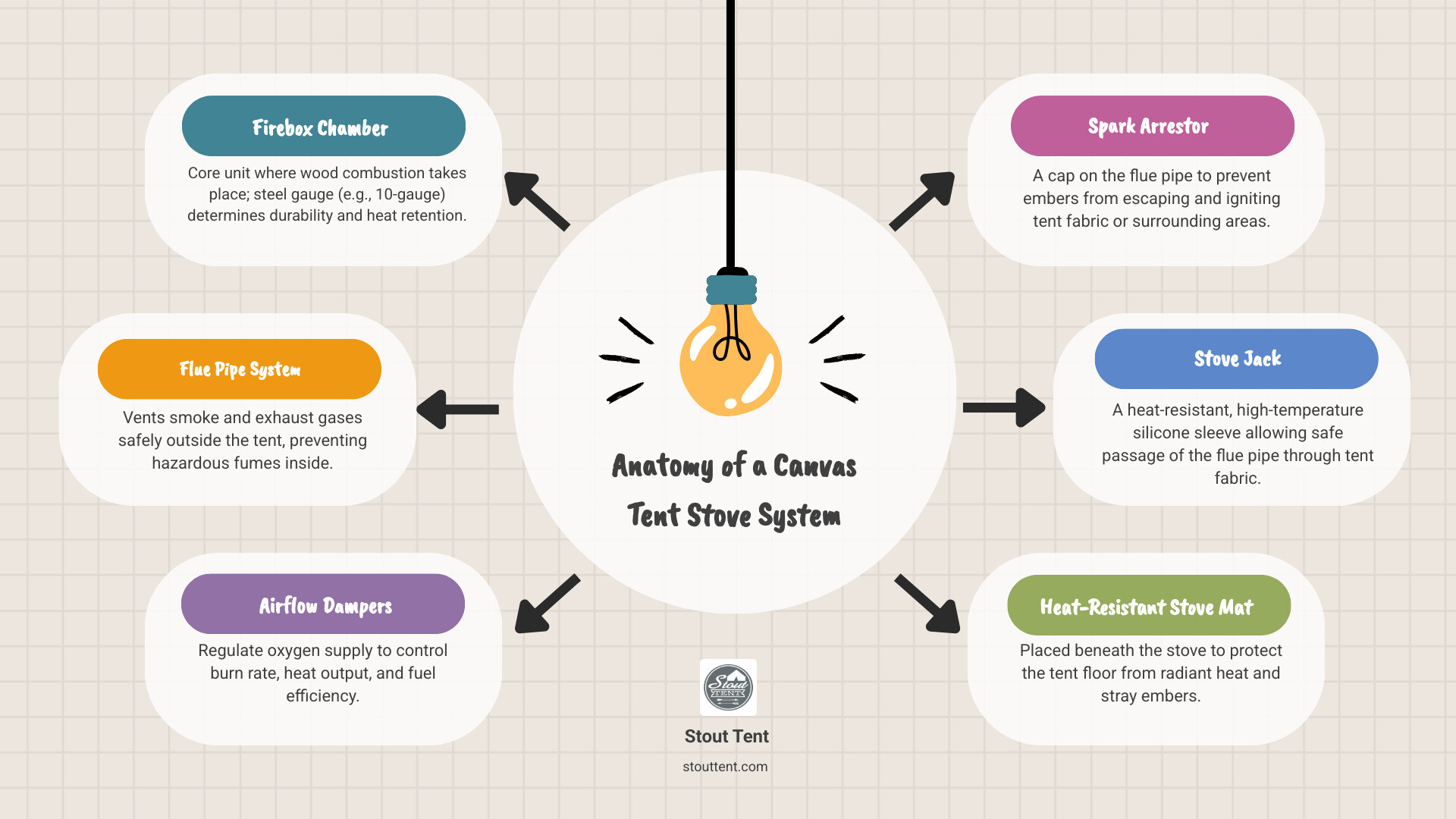

The core system includes a firebox where combustion occurs, a flue pipe system that vents smoke outside the tent, dampers for airflow control, a spark arrestor to prevent ember discharge, and a stove jack—the heat-resistant sleeve that allows safe pipe passage through canvas. Material gauge determines longevity: 10-gauge steel outperforms lighter options in high-use commercial environments, while 18-gauge cold-rolled steel offers adequate performance for moderate-frequency deployments.

Stout Tent’s expertise comes from specifying and deploying canvas tent stoves across six continents, in environments ranging from alpine snow camps to desert eco-resorts. Through years of expert-tested field trials and client feedback, the performance metrics that separate professional-grade systems from consumer alternatives have been clearly identified, ensuring optimal selection for commercial operations.

Evaluating Canvas Tent Stoves: Key Performance Metrics

When selecting a canvas tent stove for your operations, it is crucial to consider the Total Cost of Ownership (TCO) rather than just the initial purchase price. Investment-grade equipment, designed for operational efficiency and longevity, ultimately reduces replacement costs and ensures consistent performance, which is paramount for enterprise clients and high-value use cases like glamping operations in California. The selection process should focus on equipment that stands up to rigorous, repeated use, providing reliable warmth and functionality throughout its extensive service life.

Material Construction and Durability

The foundation of a high-performance canvas tent stove lies in its material construction. Professional-grade stoves prioritize robustness, with stove tops and doors often made from 10-gauge steel, and the stove body from 12-gauge steel. This heavy-duty construction ensures superior heat retention and structural integrity, crucial for the demanding environments of the Black Rock Desert or the snowy peaks of Washington. For more portable options, 18-gauge cold-rolled steel is used, offering a balance of strength and reduced weight, making it suitable for applications where ease of transport is key.

Cold-rolled steel, known for its increased strength and smoother surface finish compared to hot-rolled steel, contributes significantly to the stove’s overall durability and aesthetic. Airtight construction, achieved through precision welding and robust seals, is non-negotiable. This not only improves burn efficiency but also prevents dangerous smoke and carbon monoxide leaks into the tent. Expert-tested protocols ensure that all weld integrity is maintained, guaranteeing long-term reliability even under extreme temperature fluctuations and constant use. The longevity of these professional-grade materials means reduced downtime and fewer maintenance issues, contributing positively to your operational bottom line.

Heat Output and Burn Efficiency

The primary function of a canvas tent stove is to provide heat, and its effectiveness is measured by both its heat output and burn efficiency. Firebox volume directly correlates with the amount of fuel a stove can hold and, consequently, its ability to produce sustained heat. While specific BTU ratings are often sought, the practical application lies in a stove’s capacity to deliver consistent, overnight heat when fully loaded with wood or coal. For instance, an Outfitter Stove designed to hold a substantial fuel load can keep a large canvas tent warm through the night, a critical feature for comfort in cold climates across the US Northeast or Pacific Northwest.

Effective airflow control, managed by strategically placed dampers, is vital for optimizing burn efficiency. Dampers allow operators to regulate the oxygen supply to the fire, controlling the burn rate from a roaring blaze for rapid heating to a slow, smoldering burn for extended warmth. Using seasoned hardwood is essential for optimal performance, as it burns hotter and cleaner, reducing creosote buildup and maximizing heat radiation and convection within the tent. Proper management of airflow not only ensures a longer, more consistent burn but also minimizes fuel consumption, adding to the operational efficiency and TCO benefits.

Design Features for Professional Canvas Tent Stoves

Professional-grade canvas tent stoves incorporate specific design features that improve their functionality, durability, and suitability for commercial and high-value applications. The weight-to-durability ratio is a critical consideration; while a stove must be robust, excessive weight can impede transport. This leads to options like the Tundra Collapsible Stove, which, despite its 43 pounds, is designed for portability, collapsing down to 6 inches high by 15 inches wide by 25 inches long from a set-up dimension of 25 inches high by 15 inches wide by 25 inches long. This makes it ideal for remote deployments.

Nesting stovepipes are another ingenious feature, allowing the pipe sections to fit inside each other or the stove body itself, significantly reducing the packed volume for transport. This is particularly beneficial for operations requiring frequent relocation. Beyond the core structure, integrated accessories improve functionality. Side warming trays provide a convenient surface to keep food warm or dry small items. Five-gallon water heaters can be attached to the stove to provide a continuous supply of hot water for washing or cooking, adding considerable value to multi-day operations. These thoughtful design elements lift a stove from a simple heat source to a versatile, multi-purpose utility for a professional canvas tent setup.

Installation and Safe Operation in Canvas Tents

Implementing a canvas tent stove system requires adherence to expert-tested protocols to ensure both efficiency and, more critically, safety. A focus on system integrity and risk mitigation is paramount, protecting both your investment in the tent and the well-being of its occupants. Proper setup is not merely a suggestion but a mandatory procedure to prevent accidents and ensure the optimal performance of your heating solution.

Stove Jack Installation: A Critical Safety Component

The stove jack is an indispensable component for safely operating a wood-burning stove within a canvas tent. It is a heat-resistant fabric sleeve, typically made from high-temperature silicone, that provides a safe exit point for the stove’s flue pipe through the tent fabric. For those looking for tents already equipped for such systems, we invite you to explore our stove-ready tents.

Correct placement of the stove jack is vital. It should be positioned with ample safe clearances from flammable materials, ensuring the flue pipe does not come into direct contact with the canvas. The installation process involves identifying the right location, often pre-cut in Stout Tent’s purpose-built canvas bell tents, or carefully cutting an opening that matches the diameter of your stove’s flue pipe. This opening is then reinforced and sealed by stitching or attaching the stove jack into place. This crucial barrier protects the tent material from the extreme heat of the flue pipe, preventing burns and fire hazards.

Critical Safety Protocols for Canvas Tent Stoves

Operating a canvas tent stove demands unwavering attention to safety protocols. A mandatory carbon monoxide alarm must always be present and fully functional inside any tent utilizing a stove. Carbon monoxide is an odorless, colorless gas that can be deadly, and an alarm is your primary defense. To protect the tent floor and surrounding area from stray embers or intense radiant heat, a fire-proof stove mat is essential. These mats provide a crucial barrier between the hot stove and the tent’s flammable ground.

The spark arrestor, a cap placed at the top of the flue pipe, plays a critical role in preventing embers from escaping and potentially igniting the tent fabric or surrounding vegetation. Regular inspection and cleaning of the spark arrestor are necessary to ensure its effectiveness. Proper ash disposal procedures are also critical; hot ashes should never be placed directly on the ground or in plastic containers. They should be carefully transferred to a metal container with a lid, positioned well away from any flammable materials. It is strongly recommended to consult comprehensive guidelines, such as those found in the National Fire Protection Association’s Heating Equipment Safety Guidelines, to maintain the highest safety standards. Furthermore, maintaining tent fabric integrity means inspecting for wear and tear around the stove jack and using flame retardant treatments or heat mats to protect the canvas from sparks and intense heat. These expert-tested measures are essential for ensuring a safe and successful operation, whether in Phoenix, Arizona, or the US Pacific Northwest.

Frequently Asked Questions about Tent Stove Systems

Navigating the nuances of canvas tent stoves can raise several questions, especially for those new to their operation or seeking to optimize existing setups. This section provides clear, actionable insights to ensure your team is fully equipped for efficient and safe use.

How do you manage airflow for an efficient, long-lasting burn?

Managing airflow is the cornerstone of an efficient, long-lasting burn in a canvas tent stove. The key lies in strategic damper control and precise air intake adjustments. When starting a fire, open the dampers fully to allow maximum oxygen, promoting a rapid ignition and strong draft. Once the fire is established and the stove body is hot, gradually close the dampers to restrict airflow. This reduces the burn rate, allowing the wood to smolder rather than burn rapidly, extending the burn time significantly—often enabling an overnight burn.

Achieving secondary combustion, where gases released from the wood are burned rather than escaping as smoke, further improves efficiency. This is often indicated by small, dancing flames above the main fire bed and minimal smoke exiting the chimney. Learning to “read the flame” – observing its color and intensity – helps in fine-tuning damper settings. A bright, steady flame indicates good combustion, while a dull, lazy flame suggests insufficient airflow. Minimizing smoke output is not only a sign of efficiency but also crucial for environmental considerations and reducing creosote buildup in the flue.

What maintenance is required to ensure a long service life?

Ensuring a long service life for your canvas tent stove involves consistent and thorough maintenance. The most critical task is creosote removal from the flue pipe. Creosote, a highly flammable byproduct of wood combustion, can build up and pose a significant fire hazard. It is recommended to inspect and clean the flue pipe regularly, especially after every 10-15 uses or whenever creosote buildup of 1/4 inch or more is observed.

Regular ash cleanout is also essential; allowing ash to accumulate too much can restrict airflow and reduce efficiency. Inspecting seals and welds for any cracks or deterioration is crucial for maintaining the stove’s airtight integrity and preventing smoke leaks. Before off-season storage, thoroughly clean the stove, ensuring it is completely dry to prevent rust. Applying a thin coat of stove polish or oil can provide an additional layer of rust prevention, particularly in humid climates. Proper care and attention to these maintenance steps will ensure your professional-grade stove remains an investment that reliably serves your operations for many years.

Can you effectively cook on a canvas tent stove?

Absolutely. A well-designed canvas tent stove is a versatile appliance that excels not only at heating but also at cooking, adding immense value to multi-day operations. Many models feature flat-top cooking surfaces, allowing for direct placement of pots, pans, and kettles. This transforms the stove into a functional cooktop for preparing meals, brewing coffee, or simply boiling water for hygiene or rehydration.

Temperature control for cooking can be managed by adjusting the dampers and the amount of fuel in the firebox. A hotter fire provides higher cooking temperatures, while a slower burn can be used for simmering or keeping food warm. Accessories like small stove-top ovens can further expand cooking capabilities, allowing for baking bread or roasting small dishes. This multi-purpose functionality means your stove is not just a comfort item but a critical piece of operational equipment, reducing the need for separate cooking apparatus and streamlining your camp setup, whether you’re outfitting a glamping site in the US Southeast or an eco-resort in the US Southwest.

Conclusion: Choosing a Reliable Tent Heating Solution

Investing in a professional-grade canvas tent stove is more than just purchasing a heating appliance; it’s an investment in your operational capability, extending your season, enhancing guest comfort, and providing reliable utility in diverse environments. Our commitment to expert-tested protocols and professional-grade materials ensures that our stoves deliver unparalleled durability and reliability, offering a superior Total Cost of Ownership through reduced maintenance and extended longevity. Choosing the right system for your specific needs means evaluating material construction, heat output, burn efficiency, and practical design features, all while adhering to stringent safety protocols. With Stout Tent’s expertise, we guide you toward a heating solution that embodies performance, safety, and enduring value for your enterprise.

Ready to deploy canvas tent stoves safely and extend your operating season? Explore our stove-ready canvas bell tents and connect with our team to confirm the right stove setup, clearances, and safety components for your environment.