Why Proper Canvas Tent Care is Your Best Investment

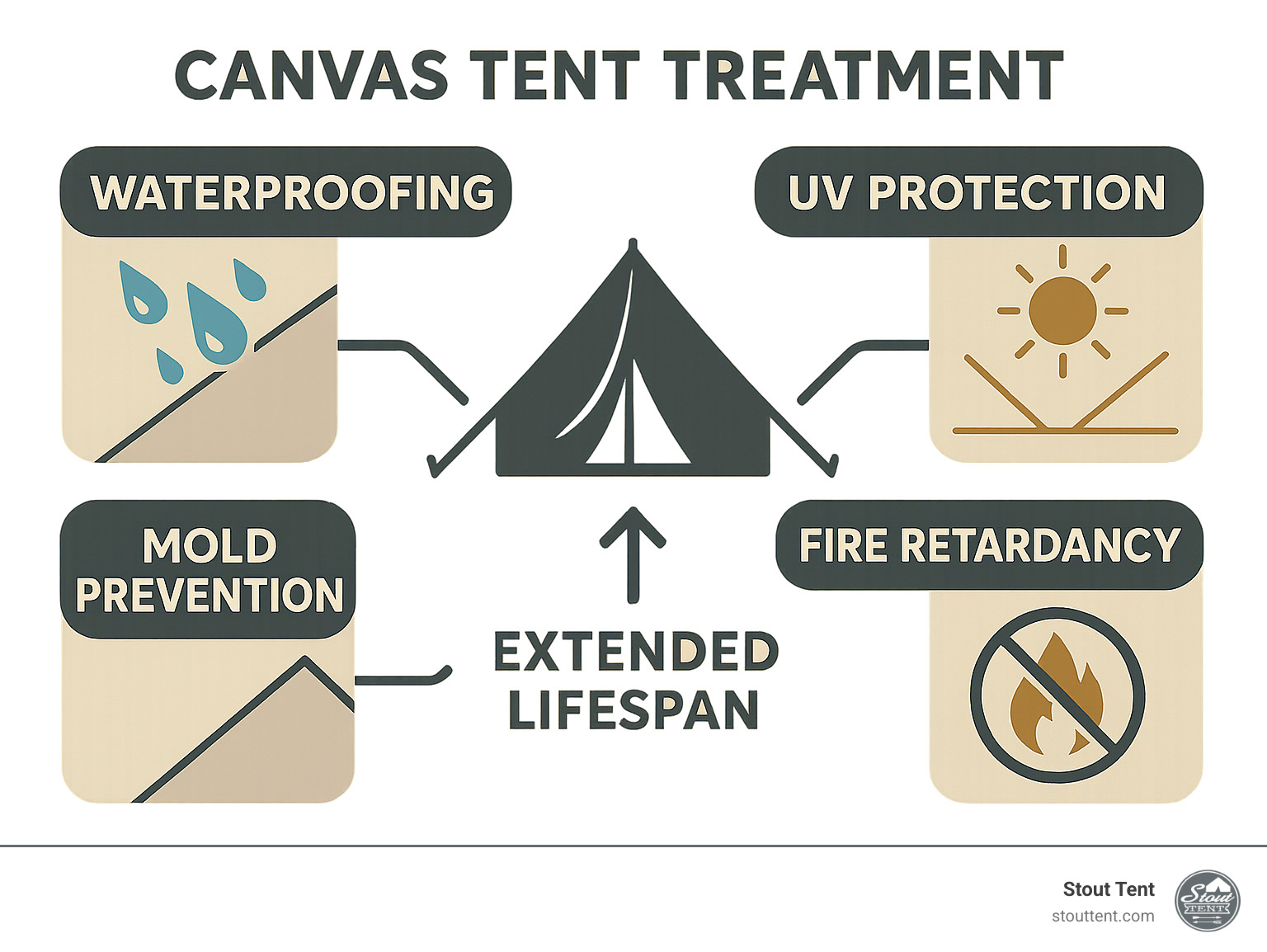

Canvas tent treatment is the single most important factor in protecting your investment and ensuring your glamping business or personal camping setup operates smoothly year-round. It’s the difference between a tent that lasts a lifetime and one that fails after a few seasons. Without proper, consistent care, even the highest-quality canvas tents can suffer from irreversible water damage, insidious mold growth, and premature deterioration.

Think of it this way: a quality canvas tent is a significant purchase. Protecting it with a few hours of maintenance and the right products is a small price to pay for decades of reliable use. Let’s break down the essential pillars of canvas care.

A Deeper Look at Canvas Tent Treatment Essentials:

- Water Repellent Treatments: This is your primary defense against rain. A good treatment doesn’t seal the fabric; it coats the fibers, causing water to bead up and roll off, just like water on a duck’s back. You should apply this annually or as soon as you notice water is starting to soak into the fabric rather than beading. This maintains the crucial breathability of the canvas.

- UV Protection: The sun’s ultraviolet rays are relentless. Over time, they break down the cotton fibers of your tent, making the fabric brittle, weak, and prone to tearing. A quality UV protectant acts like sunscreen for your tent, reflecting harmful rays and preventing this degradation. This is especially critical in high-altitude or desert locations like the US Southwest.

- Mold & Mildew Prevention: This is about more than just ugly stains. Mold and mildew are living organisms that feed on cotton fibers, literally eating your tent away. More importantly, they release spores that can cause serious respiratory issues, allergic reactions, and other health problems. Prevention through proper treatment and dry storage is paramount, as once mold sets in, it’s incredibly difficult to eradicate completely.

- Fire Retardant Coatings: For many commercial operations, glamping sites, and public campgrounds, this isn’t optional—it’s a legal requirement. Treatments must meet specific safety standards, most commonly the CPAI-84 standard, which ensures the fabric will resist combustion and self-extinguish when a flame source is removed. This is a critical safety feature, especially when using tent stoves or heaters.

- Proper Cleaning: Never use harsh detergents, bleach, or household soaps on your canvas. These chemicals can strip the existing treatments and damage the cotton fibers. Always use a pH-neutral, canvas-specific cleaner and a soft-bristle brush to gently remove dirt and grime before applying any new treatments.

- Seasoning New Tents: This is a crucial first step for any new 100% cotton canvas tent. The process involves thoroughly wetting the tent and allowing it to dry completely. This causes the cotton fibers to swell and then shrink, tightening the weave and sealing up any tiny holes in the seams. It’s a natural waterproofing process that sets the foundation for all future treatments.

Canvas has been a trusted material for portable shelters for centuries, but modern treatments can realistically double your tent’s lifespan, taking it from a 15-year investment to a 30+ year heirloom with diligent care. The key is understanding that canvas is a natural material that needs to breathe while staying waterproof—a balance that synthetic materials can’t replicate.

For glamping operators, this translates directly to a stronger bottom line: fewer tent replacements, happier guests who stay dry and comfortable, and protection from the catastrophic (and costly) damage that untreated canvas can suffer. As one industry expert noted: “Canvas tents are practically immortal if stored dry” – but only when properly treated and maintained.

I’m Caitlyn Stout, founder of Stout Tent, and I’ve spent years perfecting canvas tent treatment methods for commercial operations across six continents. My hands-on experience with canvas materials, manufacturing, and large-scale deployments has taught me that proper treatment isn’t just maintenance – it’s the foundation of a successful and sustainable glamping business.

The Ultimate Guide to Canvas Tent Treatment

When you’re investing in a quality canvas tent, understanding the different canvas tent treatment options can feel overwhelming. But here’s the thing – each treatment serves a specific, vital purpose, and knowing the differences will empower you to make the best choice for your camping trips and protect your gear for the long haul.

The most common confusion we encounter is around waterproofing terminology. People often use “waterproof,” “water-resistant,” and “water-repellent” interchangeably, but they have distinct meanings and implications for your comfort and your tent’s health.

| Treatment Type | Water Protection Level | Duration | Best For |

|---|---|---|---|

| Waterproof | Complete water barrier (often a coating) | Long-lasting | Heavy rain, permanent installations, often sacrifices breathability |

| Water-Resistant | Resists water penetration to a degree | Moderate duration | Light to moderate rain, maintains some breathability |

| Water-Repellent | Water beads and rolls off the surface | Shorter duration, needs reapplication | General weather protection, maintains full breathability |

Water repellent treatments are the gold standard and most popular choice for high-quality canvas tents. They work by creating a hydrophobic surface on the fabric’s fibers without clogging the pores in the weave. This is essential because it maintains the canvas’s signature breathability. A fully “waterproof” coating, like a layer of plastic, would trap moisture and condensation inside your tent, making the interior feel damp and clammy even when it’s not raining. A water-repellent treatment lets water vapor from your breath and body escape, keeping you dry from the inside out.

UV resistant treatments are equally important but often overlooked until it’s too late. The sun’s ultraviolet radiation is a powerful force that breaks down organic materials, including the natural cotton fibers of your tent. This process, known as photodegradation, causes the fabric to lose tensile strength, become brittle, and fade. A good UV treatment contains inhibitors that absorb or reflect this radiation, acting like a permanent sunscreen for your tent and dramatically extending its life, especially in sun-drenched environments.

Here’s where things get serious: mold and mildew resistant treatments aren’t just about aesthetics. Mold is a fungus that, if left unchecked on damp canvas, will cause permanent staining and begin to digest the cotton fibers, leading to rot and fabric failure. More critically, mold releases spores that can pose real health risks, triggering allergies, asthma attacks, and other respiratory problems. A quality treatment contains a fungicide that creates an inhospitable environment for these organisms, preventing them from ever getting a foothold. This is a non-negotiable feature for any tent, especially those used in humid climates.

For commercial operations, festivals, or certain public camping areas, fire retardant treatments (CPAI-84) aren’t optional – they’re required by law for safety and liability. These treatments involve saturating the canvas with chemicals that inhibit ignition and reduce the spread of flames. “Fire retardant” does not mean “fireproof.” A treated tent will still burn if exposed to a direct flame, but it will do so much more slowly and will often self-extinguish once the flame source is removed, providing critical time to escape. These treatments are essential for anyone planning to use a wood stove inside their tent.

The key is finding treatments specifically formulated for natural canvas. Generic waterproofing sprays from a hardware store often contain silicones or other chemicals that can clog the canvas weave, destroy its breathability, and may even react poorly with existing treatments.

Choosing the Right Canvas Tent Treatment for Your Needs

Not all canvas is created equal, and your treatment strategy must be custom to your tent’s material, your climate, and how you use it. Cotton canvas and poly-blend canvas each have unique characteristics that influence which treatments are most effective.

Pure 100% cotton canvas, like that used in Stout Tents, is the premium choice for its incredible durability, insulation, and best breathability. However, being a natural material, it requires diligent and regular treatment to perform its best. Poly-cotton blends are lighter and may dry faster, but they often sacrifice some of the breathability and insulating properties of pure cotton. Your treatment plan for a 100% cotton tent should heavily prioritize mold prevention and maintaining water repellency.

Climate considerations play a huge role in your treatment strategy. Your tent’s primary adversary changes with your location.

- In the damp, lush US Pacific Northwest or the humid US Southeast, your biggest enemy is moisture. Here, you’ll need a treatment with a powerful anti-fungal agent and you must re-apply your water repellent diligently.

- In the arid, high-elevation US Southwest, including Arizona and the Black Rock Desert, the intense, year-round sun is the main threat. Maximum UV protection is essential to prevent your canvas from becoming brittle.

- In the US Northeast, you face a combination of all factors: humid summers, intense sun, and cold, damp shoulder seasons. A comprehensive, all-in-one treatment is often the best approach here.

Usage frequency matters, too. A weekend warrior who camps a few times a year can likely get by with a thorough cleaning and re-treatment at the end of each season. In contrast, a full-time glamping operation with tents pitched for months on end may need to inspect and re-treat their canvas multiple times per year to keep them in pristine, guest-ready condition.

Many quality tents, including all Stout Tents, come pre-treated from the manufacturer. This initial treatment is designed to protect the canvas from the elements right out of the box and works in tandem with the initial seasoning process. However, this factory treatment is not permanent. Sun, rain, and even dust will gradually wear it away. Re-treating your tent is a normal and necessary part of its long-term maintenance plan, not a sign of a defect.

For more detailed guidance on selecting the perfect tent for your needs, check out our comprehensive Buyers Guides and learn more about What Treatments Should I Look For In a Canvas Tent? in our Tent Features section.